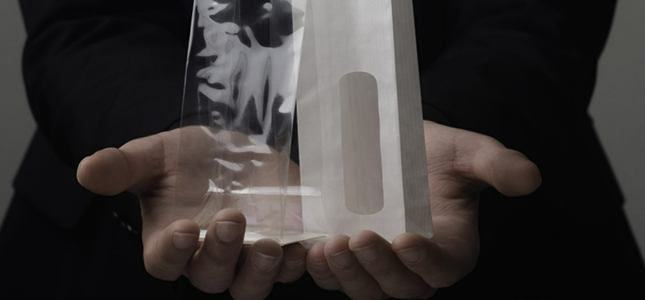

Ever wondered where the packaging for your delicious syrup waffles comes from? Chances are it was made by Cor Rijken Verpakkingen, specialist producer of high-quality custom-made polypropylene bags.

Founded by Cor Rijken in 1996, the company now manufactures more than 70 million packages a year in its own production facilities, and a further 100 million packages elsewhere, shipping to about 40 countries. Many products are custom-made, so accuracy and flexibility in logistics are critical.

When the company was introduced to nShift, via their ERP provider, AFAS, they saw a fantastic opportunity to automate shipping from order through label and tracking.

Challenge

Manual booking and label creation were slowing the process and increasing the potential for mistakes. The operation needed a way to connect an expanding carrier mix directly to AFAS, keep rules under the company’s control, and ensure every custom order shipped correctly the first time.

Solution

Cor Rijken integrated Transsmart with AFAS to drive shipping from their ERP. Orders now trigger carrier selection and label creation automatically. Shipping rules are configured once and applied consistently.

It is still possible to maintain our personal approach: everything can be adjusted to our wishes and those of our customers. This is how we can distinguish ourselves in the market.

Willem Sangers

Business Manager, Cor Rijken Verpakkingen

The platform enables Cor Rijken to link to 400+ carriers worldwide directly from AFAS, as needed, so the team can negotiate rates, switch services when needed, and onboard new carriers without rebuilding processes.

We just negotiate with the carrier. Other than that, we don’t have to take any steps. nShift makes all the adjustments and the shipping labels come out right away because everything is automated. It really runs like a well-oiled machine!

Willem Sangers

Business Manager, Cor Rijken Verpakkingen

Results

The company reports faster work, easier onboarding, and fewer mistakes because data flows from ERP straight to carrier selection and label printing. The rules-driven setup keeps shipping aligned to product and customer requirements, and labels print immediately without extra steps.

The system is much less error-prone because everything is automated. A first-class solution for us!

Willem Sangers

Business Manager, Cor Rijken Verpakkingen