In our new 2026 delivery trends report, warehouse robotics and operational twins sit firmly in the “operational excellence” bucket. Not as futuristic side projects, but as very practical levers for service, peak performance, and cost.

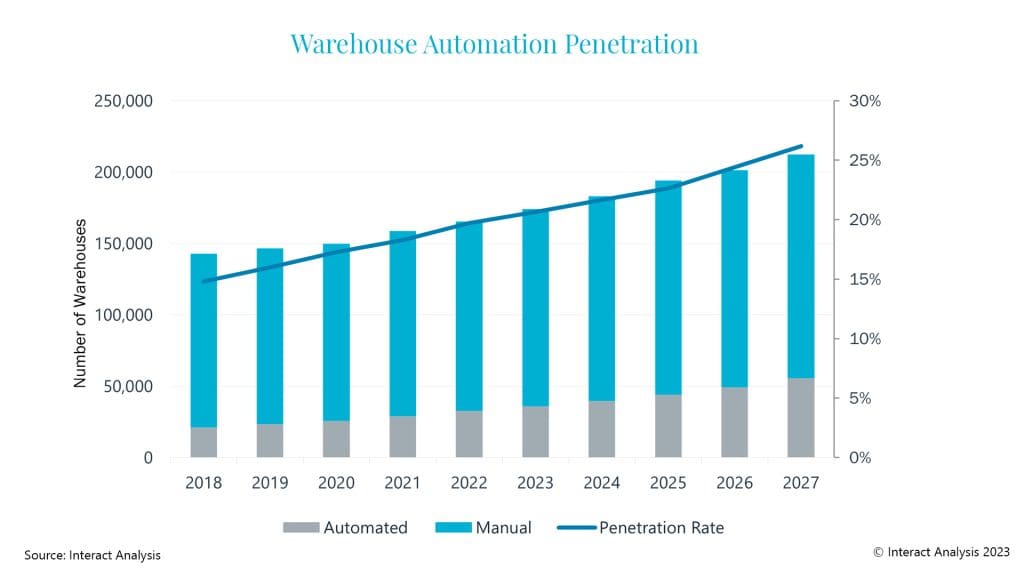

Analysts expect a sharp step up in automation. Gartner projects that by 2027 more than 75% of companies will use some form of cyber-physical automation in their warehouses. Interact Analysis estimates that around 26% of warehouses worldwide will be automated beyond basic conveyors by 2027, up from about 18% in 2021. In parallel, real deployments from operators like DHL Supply Chain and Locus Robotics already count more than 500 million robot-enabled picks across dozens of sites, with 2–3x productivity gains versus manual cart picking. Amazon has passed the one-million-robot mark in its operations.

Alongside the robots, “virtual warehouses” are becoming standard. Operational digital twins let teams model layouts, flows, storage strategies, and automation assets in a virtual environment before they move a single rack on the floor.

Together, these trends make “how we design and run the warehouse” a core 2026 logistics trend, directly linked to delivery performance.

From warehouse projects to delivery performance

On paper, warehouse robotics looks like a pure operations topic. In practice, it sits right at the heart of delivery management and logistics trends for 2026:

Cut-off times and promise reliability

AMRs, shuttles, and automated sortation make it easier to hold later order cut-offs without risking missed carrier departures.Peak resilience

Automation and twins help teams absorb volatile ecommerce peaks without relying solely on overtime and temporary labor.Network flexibility

When you can simulate new flows and volumes in the twin, it becomes easier to add new carriers, services, and order profiles without destabilizing the DC.Data for control towers and delivery management

Automated sites generate cleaner event streams (start, pick, pack, handover) that can feed control towers, transport management, and delivery experience platforms, improving ETA quality and exception handling further downstream.

This is why we treat warehouse robotics and operational twins as a core 2026 delivery topic rather than a standalone operations project.

What warehouse robotics and twins look like in 2026

Across Europe, we see a few common patterns in how this trend actually shows up:

Robotics fleets as peak-management tools

Autonomous mobile robots, shuttle systems, and automated sorters are used to level workloads across shifts, absorb late-day order spikes, and support tighter service commitments.

Twins as a standard design step

Layout changes, new SKUs, new automation assets and even new service offerings are trialed in the operational twin first. Teams test congestion hot spots, slotting strategies, and pick paths virtually before committing capital.

Hybrid warehouses rather than all-or-nothing

Most facilities will still combine manual, semi-automated, and fully automated zones. The competitive difference comes from knowing exactly where to deploy robotics first and how to link those zones into one coherent flow.

Closer integration with the rest of the stack

WMS, robotics control systems, and delivery or transport platforms share real-time events. The goal is a continuous picture from order creation to parcel handover, not separate silos for “inside the DC” and “after the dock door.”

Source: Interact Analysis

Retailers with their own DCs: Turn robotics into a peak-management engine

For retailers and brands that operate their own distribution centers, this is really about control:

Use twins to choose your starting point

Instead of debating where to automate in the abstract, use an operational twin to test different scenarios. Where does travel time spike? Which zones create repeated congestion? Which changes unlock later cut-offs or reduce weekend overtime?

Link automation decisions to customer promises

Tie each robotics or layout decision to something commercial: same-day cut-off in key markets, more reliable next-day delivery, or faster processing of returns. That makes it easier to secure investment and align merchandising, ecommerce, and operations around the same goals.

Connect the DC to your delivery management layer

Ensure that warehouse events flow into your delivery management or transport management platform in real time. When orders move from “picked” to “packed” to “handed over,” that should immediately update ETAs, tracking, and exception queues.

Plan the roadmap, not just the project

Treat robotics and twins as a multi-year capability, not a one-off installation. Decide which sites and flows you will phase in next and what that means for carrier contracts and delivery propositions.

3PL providers and parcel carriers: Automation as proof you can scale

Third-party logistics providers and parcel carriers are under pressure to demonstrate that they can handle growth, volatility, and tighter SLAs. In the 2026 delivery trends landscape, robotics and twins are concrete proof points:

Make your automation roadmap part of every major bid

Shippers want to see where you already use robotics, what throughput those sites achieve, and what the next phases look like. Turn that into a simple, visual roadmap you can share in RFPs and QBRs.

Instrument automated hubs for data-driven storytelling

Capture metrics such as lines picked per hour, error rates, dwell time in sortation, and peak-day performance. Feed these into customer control towers and performance dashboards so shippers see the benefit in their own tools, not just in a slide.

Use twins to de-risk new business

When you pitch for large, time-critical contracts, use an operational twin to simulate the additional volume through key sites. That lets you show what the flow will look like with and without added automation, which supports more confident commercial commitments.

Link warehouse events to delivery promises

Integrate warehouse automation events with your multi-carrier and delivery management stack so that any disruption in the hub is visible early and can trigger proactive customer communication, re-routing, or reprioritization.

Warehouse tech providers: Make the warehouse visible to the whole chain

For WMS vendors, robotics integrators, and logistics platforms, the key 2026 logistics trend is convergence. Customers want systems that behave like one backbone, not separate islands:

Prioritize deep, clean integrations

Focus on real-time, well-documented integrations between WMS, robotics control systems, and delivery or transport management platforms. The goal is a single, coherent event stream from “order created” to “shipment delivered”.

Design for control towers and analytics

Ensure that events from automated sites can be consumed by control towers and analytics tools in a standard format. That is what lets shippers and 3PLs use your data for network-wide forecasting, exception management, and service assurance.

Expose twin-ready data models

Build data models and APIs that make it easy to plug operational twins into your systems, so customers can run simulations without extensive custom integration.

Combine warehouse and delivery insight

Work with delivery management platforms like nShift to help customers see how changes in pick, pack, and cross-dock processes impact carrier handovers, ETAs, and customer experience. That is where warehouse robotics becomes obviously relevant to delivery outcomes.

Workforce and HR leaders: Designing human-robot teams

Warehouse robotics is also a people trend. As you move through 2026, HR and operations leaders have a critical role in making this change sustainable:

Define new roles early

Map the skills and roles you will need for more automated operations: robot fleet supervision, maintenance, data analysis, continuous improvement. Create training paths so existing staff can move into these roles where it makes sense.

Use twins as change-management tools

Show teams how the warehouse will change using the digital twin, not just floor plans. This makes it easier to explain new processes, safety rules, and performance expectations.

Measure ergonomics as well as throughput

Use data from robotics and twins to improve working conditions: shorter walk distances, fewer heavy lifts, clearer zones of responsibility. This helps with retention and supports a more positive narrative around automation.

Communicate how data will be used

Be explicit about how performance data from robots and systems will support coaching, planning, and safety, rather than being seen only as surveillance.

Bringing it back to the 2026 delivery trends landscape

Warehouse robotics and operational twins might sit inside the four walls of a DC, but they are tightly connected to the 2026 delivery trends as a whole:

- AI and predictive analytics decide what should happen.

- Robotics and twins determine how quickly and reliably it happens in the warehouse.

- Platformization and delivery management platforms make that performance visible to carriers, customers, and AI agents.

If delivery is where promises are kept, then warehouse robotics and operational twins are increasingly the engine room that makes those promises realistic.

Get the full picture

This article is part of our research on “The future of delivery: Key trends shaping 2026”, which covers ten interconnected trends across AI, platforms, regulation, resilience, and retail demand.

This article is part of our research on “The future of delivery: Key trends shaping 2026”, which covers ten interconnected trends across AI, platforms, regulation, resilience, and retail demand.

For the complete picture, with detailed data, references, and recommendations for each stakeholder group, download the full report: Future of delivery 2026.

About the author

Thomas Bailey

Thomas plays a key role in shaping how new features and platform improvements deliver real value to customers. With a background spanning product, tech, and go-to-market strategy, he brings a pragmatic view of what innovation looks like in practice and how to make delivery experiences work harder for your business.