Forecasting and reporting used to tell logistics teams one thing: what went wrong last month. That is no longer enough.

AI-driven forecasting can already cut forecast errors by 20–50%, reduce lost sales and product unavailability by up to 65%, and trim warehousing costs by 5–10%. Early adopters of supply chain digital twins report 20–30% better forecast accuracy and up to 80% fewer delays and downtime when they simulate decisions before execution.

In 2026, these are becoming core delivery infrastructure in Europe. Predictive analytics, control towers, and end-to-end digital twins decide who sees a problem early, who can re-route in time, and who is left explaining yet another missed promise.

This article looks at what this 2026 delivery trend really involves, why it matters in European delivery networks, and what different stakeholders can do now to move from hindsight to “know before it breaks”.

What “predictive delivery” actually means

There are three building blocks behind this trend:

- Predictive analytics

Statistical and AI models that anticipate demand, capacity, and disruption before they hit operations. In delivery and logistics that often means:

- Demand and order forecasting

- Capacity and lane utilization forecasts

- ETA predictions and delay risk scores

- Control towers

A cross-functional “pane of glass” sitting on top of transport, warehouse, and order systems. The best control towers do more than visualize data. They:

- Normalize events from many carriers and systems

- Highlight exceptions that matter

- Trigger or recommend specific actions

- End-to-end digital twins

A living digital replica of your network: nodes, lanes, constraints, and costs. Teams can simulate changes before committing in the real world:

- “What if this hub goes down?”

- “What if we move this inventory pool?”

- “What if we switch 20% of volume to out-of-home?”

Put together, the competitive pattern for 2026 looks like this:

Predictive signal → Recommended response → Simulated impact → Executed action

Instead of:

Spreadsheet → Email thread → Late reaction.

Why this matters so much in 2026

European delivery networks are complex by design:

- Multi-node and multi-modal flows

- Cross-border moves and customs steps

- Disruption from climate events, strikes, and geopolitics

In that environment, waiting for weekly or monthly reports is effectively a decision to manage by firefighting.

Predictive analytics, control towers, and digital twins change the rhythm:

- Demand and capacity shifts are flagged before they hit the network

- Teams can test alternate routes, carrier mixes, and hub strategies in simulation

- Trade-offs between cost, service level, and risk become visible instead of implicit

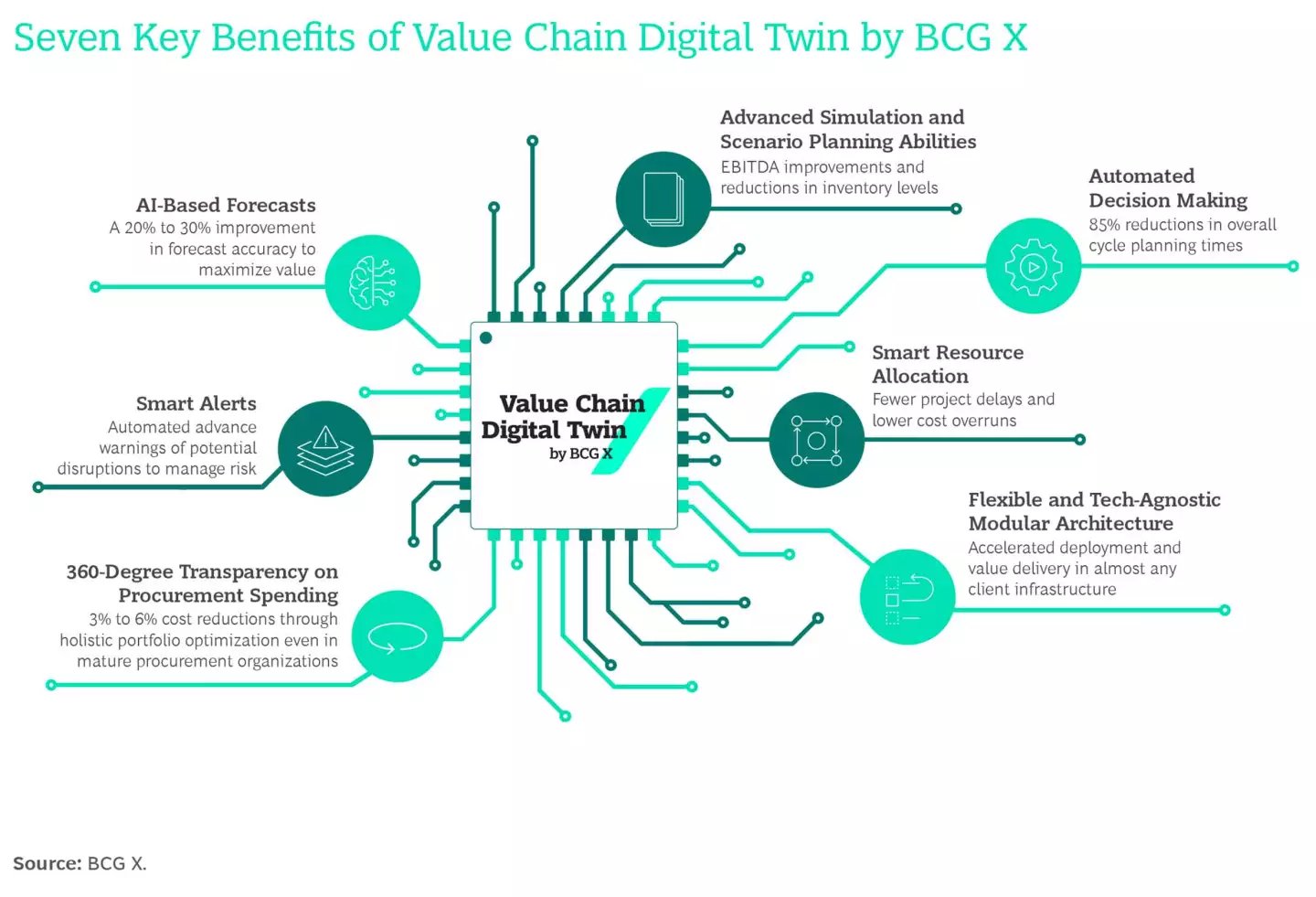

Source: BCG

The catch is that none of this works without solid data. Fragmented status codes, missing timestamps, or opaque carrier events break trust quickly. When planners stop believing the tower or the twin, they revert to spreadsheets and phone calls.

The winners in 2026 will not be the companies with the flashiest graphics. They will be the ones that:

- Capture reliable, timely events across carriers and systems

- Standardize how those events are modeled and shared

- Embed predictive tools into everyday workflows, not just quarterly reviews

How this trend connects to the other 2026 delivery shifts

This predictive layer does not live in isolation. It reinforces several other 2026 delivery trends:

- AI and autonomous decision-making

Predictive models and twins are where AI becomes “boringly valuable”: better ETAs, smarter allocation, more accurate delivery promises. - Platformization and API ecosystems

Control towers and twins need normalized events from many carriers and systems. That is only practical when data flows through standard APIs instead of custom point-to-point builds. - Supply chain resilience and targeted nearshoring

As networks rebalance “in Europe for Europe”, twins help test new lanes, regional hubs, and buffer strategies before money is spent. - Regulatory backbone and data

Emissions reporting, eFTI, and carbon pricing all assume a level of shipment-level data quality that predictive tools can leverage and improve.

That is why predictive analytics and digital twins sit so close to the center of 2026 logistics trends. They are both a trend in their own right and the operating system underneath several others.

If you run retail and ecommerce operations

2026 reality

Retail and ecommerce leaders are under pressure to protect service levels and working capital at the same time. Forecasting errors show up as stockouts and over-stock, and any blind spot in the delivery network quickly becomes a broken promise at checkout.

Moves to make now

- Start with the questions, not the tech.

Identify 2–3 delivery questions that, if answered earlier, would change decisions. Examples:- “Where are we most at risk of late deliveries next week?”

- “Which SKUs drive the cost of emergency shipments?”

- “Which postcodes consistently create failed first attempts?”

- Put predictive insights where planners already work.

Instead of building a new dashboard, embed alerts and risk scores into existing order allocation screens, transport planning tools, and customer service consoles. - Link predictive decisions to customer metrics.

Track how forecast quality and twin-driven changes affect fill rates, delivery promise accuracy, and WISMO volume. That is what the Board and CFO will care about.

If you manage carrier networks or 3PL operations

2026 reality

Carriers and logistics service providers are judged on reliability and transparency as much as base rates. Shippers expect better ETAs, earlier warning of disruption, and granular data they can feed into control towers and twins.

Moves to make now

- Invest where patterns are repeatable.

Focus predictive models on linehaul, hub and terminal operations, and standard delivery flows where you already have dense data. That is where forecasting and simulation will pay off fastest. - Treat event data as a product you sell.

Clean, timestamped events for pickup, handover, delays, and delivery are no longer a bonus. They influence tenders and contract renewals. Make sure APIs expose these in a consistent, machine-readable way. - Use your own twin before a shipper builds theirs.

Simple network twins that let you test route changes, depot moves, or consolidation strategies will help you go into shipper conversations with options, not just rates.

If you build logistics platforms and control towers

2026 reality

Platforms sit at the heart of this trend. Without normalized events, clear schemas, and stable APIs, predictive analytics and digital twins remain slideware. At the same time, shippers and carriers are wary of platforms that promise too much and deliver fragile models.

Moves to make now

- Standardize events first, AI second.

Create a clean, well-documented event model for shipments, orders, and exceptions. Make that model visible to customers and partners. Most “AI readiness” problems in 2026 will be event problems in disguise. - Ship reference patterns, not just features.

Offer out-of-the-box patterns such as:- “Predict at-risk shipments and trigger proactive notifications”

- “Score lanes by disruption risk next week”

- “Simulate moving 20% of parcels to out-of-home in these cities”

Then show how customers can configure them without custom engineering.

- Expose twin-ready data through APIs.

Ensure your APIs make it easy to pull clean network data into customers’ own twins and analytics stacks, while keeping access and governance under control.

For nShift specifically, the Future of delivery 2026 report positions delivery and experience platforms as shared infrastructure for this kind of cross-carrier, cross-merchant data. The more predictive your customers want to be, the more they need normalized events across 1,000+ carriers, not another isolated data silo.

If you lead IT, data, or analytics

2026 reality

IT and data leaders are the ones who decide whether predictive delivery stays in pilot mode or becomes part of the operating model. The challenge is less about picking tools and more about building a backbone that everything can plug into.

Moves to make now

- Define a shared “delivery data contract”.

Agree on what a shipment is, what events exist, what fields are mandatory, and how time and location are captured. Apply that contract across TMS, WMS, OMS, ecommerce, and carrier integrations. - Connect predictive models to operational levers.

For every model, answer:- “Who will see this signal?”

- “What will they do differently?”

- “How will we measure the impact?”

- Plan for observability.

Monitor forecast error, model drift, and data quality issues over time. Make it clear when humans should override the model and how those overrides feed back into learning.

Get the full picture

This article is part of our research on “The future of delivery: Key trends shaping 2026”, which covers ten interconnected trends across AI, platforms, regulation, resilience, and retail demand.

This article is part of our research on “The future of delivery: Key trends shaping 2026”, which covers ten interconnected trends across AI, platforms, regulation, resilience, and retail demand.

For the complete picture, with detailed data, references, and recommendations for each stakeholder group, download the full report: Future of delivery 2026.

About the author

Thomas Bailey

Thomas plays a key role in shaping how new features and platform improvements deliver real value to customers. With a background spanning product, tech, and go-to-market strategy, he brings a pragmatic view of what innovation looks like in practice and how to make delivery experiences work harder for your business.