Last update: 17.06.2025

In this blog:

- Intro

- What is parcel damage?

- Why parcel damage matters for your bottom line

- When and where does parcel damage occur?

- Some insightful data from previous years

- How to prevent parcel damage: actionable strategies

- Damage prevention checklist (5 quick wins)

- Final thoughts: get ahead of parcel damage

- Further reading: Parcel damage FAQs

Intro

It can be really disappointing when you’re waiting for an item to arrive and when it turns up, your parcel is damaged – especially if it’s a gift! As customers, we all expect our items to turn up looking brand new, with no dents, tears, or holes. Poor packaging can often result in the item being damaged, or just an overall poor quality delivery experience, as no one wants to have to worry about their item.

Parcel damage is one of the most overlooked yet critical challenges in e-commerce and logistics. Whether you're shipping tech devices, clothing, or furniture, even one damaged parcel can trigger customer dissatisfaction, costly returns, and long-term brand harm.

In this blog post, we’ll define what parcel damage is, explore why it matters to your business, and give you proven ways to reduce it—while still keeping fulfillment costs under control.

What is parcel damage?

Parcel damage means harm to the packaging or the product inside it. That can include the outer carton being crushed or torn. Or it can be the product moving around too much and being damaged because the inner packaging wasn’t sufficient.

Damage can happen in many forms. Boxes might be dented during loading, fragile goods can rattle loose in transit, or liquids may leak from poorly sealed items. Even subtle internal impacts—like a jar hitting another in a box—can cause a return.

Whatever the cause, damage leads to increased returns, a poor customer experience, and more cost for the retailer.

And those costs aren't just operational. They can affect long-term brand trust, increase negative reviews, and erode customer retention.

Why parcel damage matters for your bottom line

Damage to a parcel impacts the customer experience.

Today’s consumers expect their orders to arrive intact, quickly, and without friction. When that expectation is broken, the impact can be immediate—poor satisfaction scores, higher churn, and rising support inquiries.

It often results in a return, which brings with it a replacement or refund cost. It also means a product can’t be resold, so it becomes waste.

Beyond just customer perception, damage drives up your operational costs. From restocking to reverse logistics, every damaged parcel represents not just lost goods but also additional labor, transport, and sometimes even regulatory compliance burdens.

When and where does parcel damage occur?

Damage can happen at nearly every step of the shipping journey. Identifying where your parcels are most at risk can help you build more resilient processes.

| Stage | Common Risks |

|---|---|

| Picking & Packing | Incorrect box size, poor cushioning, rushed packing |

| Warehouse Handling | Dropping, pallet stacking issues, equipment collisions |

| In Transit | Rough handling, conveyor damage, vibration, climate |

| Final Delivery | Mishandling at the doorstep, rain exposure, theft |

Some insightful data from previous years

Parcel damage may include the packaging being damaged, poorly packaged, or even the goods inside being maltreated. In order to understand how common this type of damage is, we asked 1,000 respondents whether they’d received a damaged parcel before.

In our Consumer Home Delivery Survey from 2021 (and available to download on IMRG’s website) we’ve collated a variety of data trends in collaboration with IMRG and Maru.

Have you or anyone in your household ever received an item that was damaged?

(Source: Maru, nShift and IMRG Home Delivery Report)

The trend line shows an interesting pattern from 2010 to 2021, as the number of people receiving damaged goods have varied, then slowly increased from 2017 (dipping slightly this year). Those receiving damaged goods tends to be between 40-60% of respondents, which is not an insignificant amount. Back in 2021, over half of respondents said they had received damaged parcels, making it the third consecutive year for which the majority answered ‘yes’. Damaged goods are becoming more common, however, you may be left asking, why?

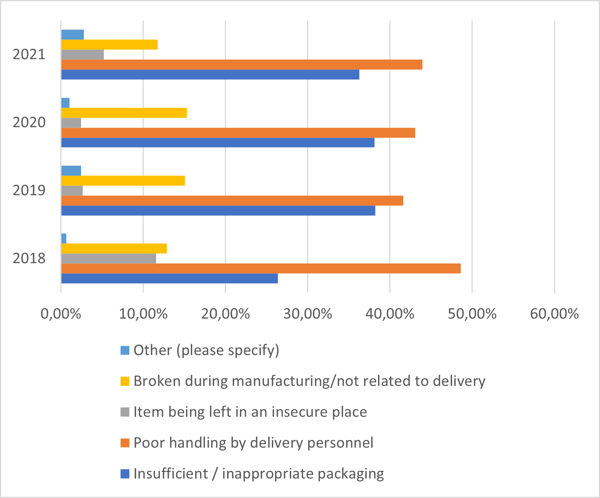

In your opinion, why did the damage occur?

(Source: Maru, nShift and IMRG Home Delivery Report)

To find out exactly why peoples’ parcels were being damaged, we then asked those who answered ‘yes’, to elaborate on why they thought the damage had occurred. The most popular answer has consistently been poor handling by the delivery personnel, meaning many people are concerned delivery drivers have mishandled their items. Similarly, insufficient packaging has always been the secondary concern. The item being left in an insecure place has actually decreased since 2018 up until 2021, suggesting there are more protocols in place for tracking and securing parcels once they arrive. These could include the ability to GPS track your parcel, and to change selected safe spots, such as porches, letterboxes, and neighbors' houses.

So, parcel damage has been increasing for a few years ago in a row, although seen slight improvement in 2021 since the previous year. It’s important to ensure that damage is minimized, as it can create a negative delivery experience for the customer.

How to prevent parcel damage: actionable strategies

At nShift, we believe the best approach is to prevent damage in the first place. But where do you start?

That’s the right mindset—and prevention requires attention to every layer of your logistics process. Below are expanded strategies that combine packaging best practices, employee training, and smart tools to reduce risk.

1. Use the right packaging materials

- Double-walled cardboard for heavy/fragile items

- Bubble wrap, foam-in-place, molded pulp, air pillows

- High-strength tape to reinforce seams and base

2. Optimize box size

Use the smallest box that provides a secure fit. This prevents shifting during transit and avoids overpacking materials, which increases cost and waste.

3. Internal bracing & moisture protection

Use inserts, dividers, and liners—especially for liquids or electronics. Weather-resistant packaging helps avoid issues during rainy seasons or cold chain deliveries.

4. Train your packing team

Standardize your packing methods across teams. Use SOPs and conduct regular training to avoid variability and reduce costly mistakes.

5. Collect and analyze damage data

Record every incident: where it happened, what product, and which carrier. Then review patterns and adjust strategies proactively.

6. Align with carrier SLAs

Collaborate with carriers using shared KPIs and hold them accountable for damage thresholds and claims management.

Damage prevention checklist (5 quick wins)

- Evaluate if box + internal packaging match product weight

- Seal with industrial-grade tape on all seams

- Label packages clearly as fragile or orientation-sensitive

- Track and document any damage consistently

- Adjust based on real-world damage analytics

Final thoughts: get ahead of parcel damage

Damaged parcels increase costs and dent a brand’s reputation. And they’re largely preventable. With the right systems in place, retailers and warehouses can mitigate the risk of damage – reducing costs and enhancing customer satisfaction.

Reducing parcel damage is not a guessing game—it’s a strategy. Through better packaging, proactive data use, team training, and carrier collaboration, you can deliver a better customer experience and increase long-term profitability.

It’s all in the delivery

From checkout to emissions, nShift gives you full control of delivery management at every step — with branded experiences, smarter shipping, and access to 1,000+ carriers.

Explore the nShift platformFurther reading: Parcel damage FAQs

What causes parcel damage during shipping?

How can I prevent packages from being damaged in transit?

What are the best packaging materials to reduce shipping damage?

How does parcel damage affect my business costs?

Can better packaging reduce e-commerce returns?

How can I track where parcel damage is happening?

Does labeling a package as fragile really help?

What role do shipping carriers play in parcel damage?

How can I choose the right packaging strategy for my business?

What is the average parcel damage rate in e-commerce?

Author

Gregory Mannix

Delivery Expert

With over 20 years of experience in SaaS, ecommerce, and logistics, Greg Mannix helps retailers and logistics providers streamline delivery operations. His expertise includes optimizing carrier management, enhancing tracking visibility, and simplifying returns to improve efficiency and customer satisfaction.

About the author

Gregory Mannix

Delivery Expert

With over 20 years of experience in SaaS, ecommerce, and logistics, Greg Mannix helps retailers and logistics providers streamline delivery operations. His expertise includes optimizing carrier management, enhancing tracking visibility, and simplifying returns to improve efficiency and customer satisfaction.