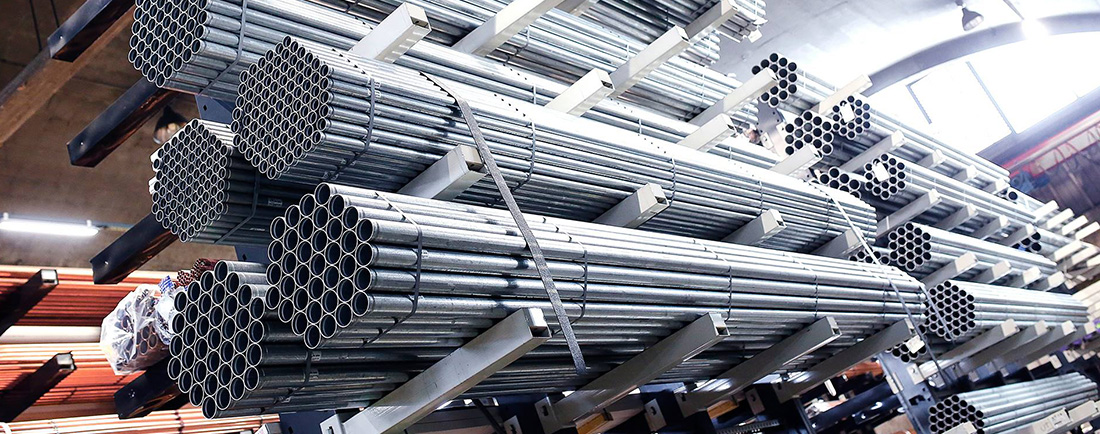

Dahl Suomi is part of Saint-Gobain, a Fortune Global 500 company that designs, manufactures and distributes materials for construction, transport and industry. As Finland’s leading wholesaler of HVAC products, the business ships hundreds of thousands of parcels each year to customers across the country. With growing volumes and rising expectations, Dahl Suomi needed a more dependable and efficient way to manage delivery information at scale.

Challenge

Before modernising their setup, Dahl Suomi relied on warehouse teams across Finland to manually enter data generated by their custom-built ERP. This created unnecessary delays, added carrier costs and led to avoidable errors. These mistakes placed extra pressure on customer support teams, who often struggled to provide accurate arrival updates without reliable data. The business needed an integrated system that could automate workflows, strengthen accuracy and give every site consistent shipment visibility.

Solution

Integrating delivery management directly into their ERP and Leanware WMS removed most manual steps across 18 sites. Automation reduced processing time and helped optimise carrier spend, while more accurate shipment data made daily work less error-prone.

The company also gained the ability to analyse routes and performance using real shipment data.

Thanks to nShift, we now have lots of package and shipment data that we can analyze to identify more effective delivery routes. This helps us not only reduce costs but also improve our delivery services, which ultimately enables us to grow revenue as well – because better, faster deliveries create happier customers, which leads to more sales.

Vaino Pokki

Training and Development Specialist, Dahl Suomi

Visibility improved significantly. Customer service teams can now see which carrier has taken a shipment, where it is in the process and when it is expected to arrive. This simplifies customer communication and reduces investigation time.

The setup also adapts to different warehouse environments. Smaller sites work with the interface directly, while the large Helsinki warehouse operates through its WMS, where nShift runs quietly in the background.

At our smaller warehouses, for example, team members interface with nShift directly. But at our large Helsinki warehouse, where we have implemented a WMS, it works away invisibly in the background without people even really knowing it’s there. So while everyone is connected to the same system and data, the user experience can vary according to the needs of the team.

Vaino Pokki

Training and Development Specialist, Dahl Suomi

Results

With automation and visibility in place, Dahl Suomi now operates a faster and more reliable delivery process. Manual errors have reduced, carrier-cost optimisation has improved and customer service teams can respond instantly with accurate delivery information.

Lots of customers call us asking when their packages are likely to arrive. Now, all we have to do is go into the nShift portal and we can immediately see which carrier has taken it for delivery and where it is in the process.

Vaino Pokki

Training and Development Specialist, Dahl Suomi

Dahl Suomi now has a scalable foundation for handling high parcel volumes across all 18 sites, supporting both operational efficiency and a stronger customer experience.