Last update: 29.07.2025

In this blog:

- Handling returns

- What is reverse logistics?

- The hidden costs of poor reverse logistics

- How to avoid waste and save money with reverse logistics

- Reverse logistics as a competitive advantage

- Further reading: Cost of poor reverse logistics FAQs

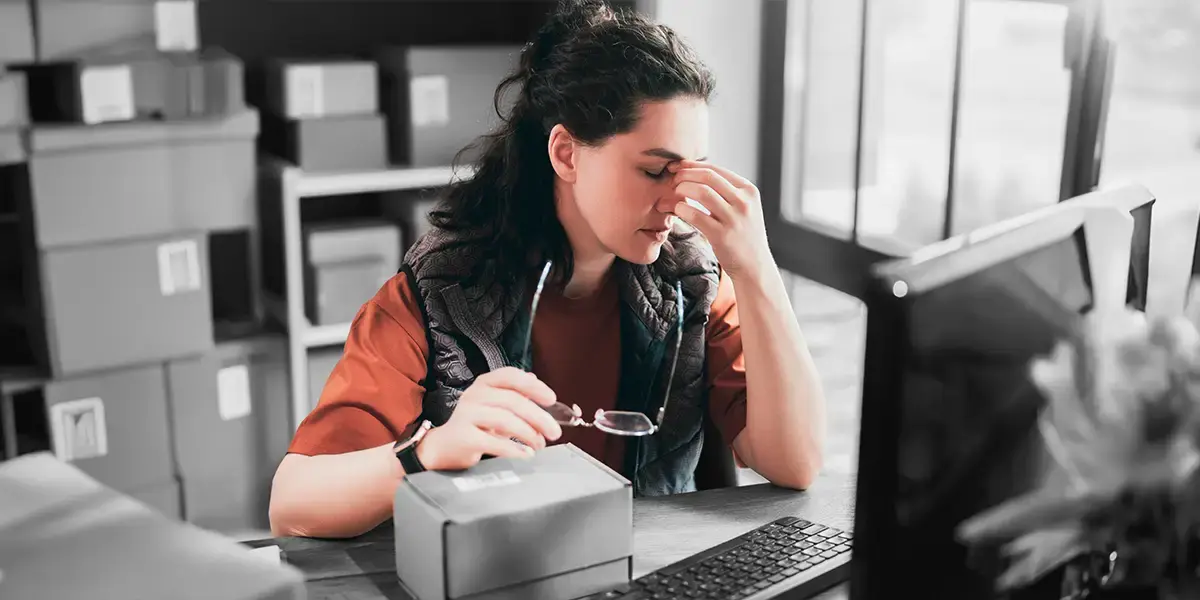

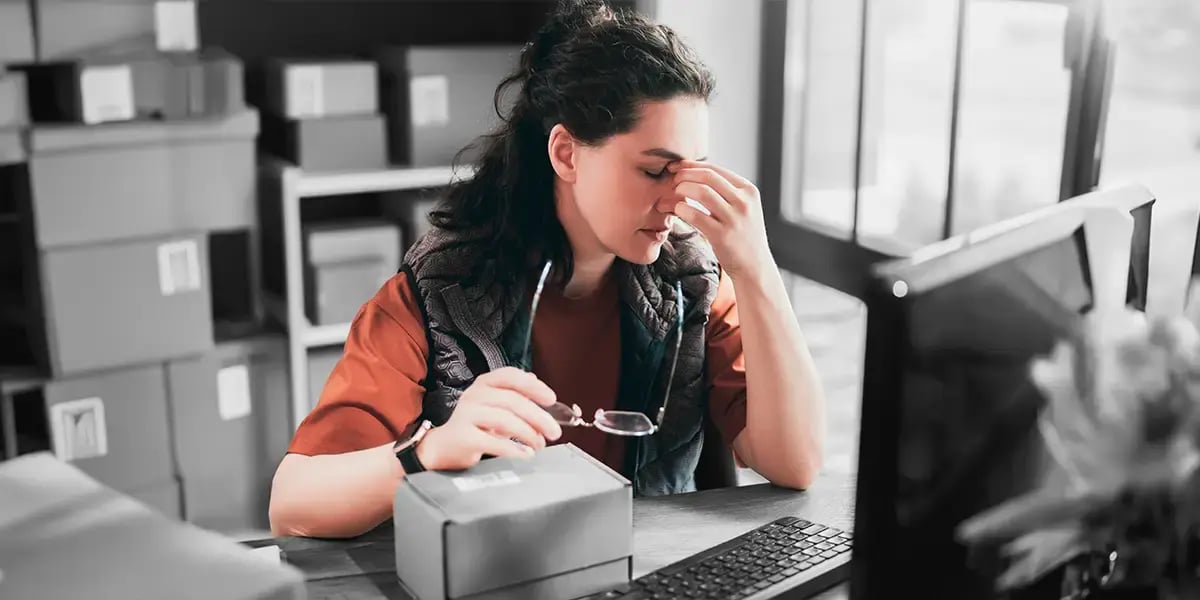

Handling returns

Handling returned products can be a significant expense for businesses, particularly in e-commerce and retail sectors. As the volume of online shopping grows, so too does the number of returns. That’s why effective reverse logistics—how a company handles returned or recycled goods—is no longer optional. It’s essential for saving costs, increasing sustainability, and improving customer satisfaction.

But when reverse logistics are poorly managed, the impact goes far beyond minor inefficiencies. Businesses can suffer from operational bottlenecks, reputational damage, and serious financial losses.

What is reverse logistics?

Reverse logistics refers to the process of moving goods from customers back to the seller or manufacturer. It includes returns, recycling, refurbishment, and disposal. Unlike traditional logistics—which focuses on getting products into customers’ hands—reverse logistics requires businesses to operate in reverse: collecting, sorting, processing, and either restocking or disposing of returned items.

The hidden costs of poor reverse logistics

Ineffective reverse logistics practices can quietly drain your bottom line. Here are some key ways poor reverse logistics can harm your business:

Increased operational costs

When returns are handled inefficiently, transportation, warehousing, and labor costs can spike. Delays in processing returned items mean that products sit idle in warehouses longer, taking up valuable space and requiring additional handling. These inefficiencies quickly add up, especially during peak return periods like post-holiday seasons.

Reduced customer satisfaction

Returns are an integral part of the modern shopping experience, especially online. If customers face delays, confusing return policies, or unhelpful support, they’re less likely to buy from you again. Research shows that customers now expect seamless return processes, and failing to meet those expectations leads to lost loyalty and lower lifetime customer value.

Increased waste and lower recovery value

Returned products that aren’t promptly inspected or processed often go unsold. Items may become outdated, damaged, or non-resalable. Instead of being restocked or refurbished, these items may end up as waste—hurting both the environment and your profit margins.

Damage to brand reputation

Today’s consumers are more environmentally conscious than ever. A poor reverse logistics process can signal to customers that your business doesn’t prioritize sustainability or customer satisfaction. Word-of-mouth reviews, social media posts, and low ratings can harm your brand image, leading to long-term reputational damage.

How to avoid waste and save money with reverse logistics

Thankfully, there are several practical steps businesses can take to turn reverse logistics into a cost-saving and customer-centric advantage.

Implement a robust returns management system

Technology plays a key role in streamlining returns. A centralized system allows you to track each item throughout its return journey, from customer drop-off to final resolution. This improves visibility, speeds up processing, and enables better decisions—such as whether to restock, repair, recycle, or dispose of the product.

According to the Reverse Logistics Association, businesses can recover up to 12% of their revenue through effective returns management.

Optimize transportation and storage

Efficient transportation and storage can significantly reduce reverse logistics costs. Tactics include consolidating return shipments, choosing fuel-efficient transport options, and minimizing time in storage. Automation and warehouse management systems can also reduce labor costs and error rates.

A study by Accenture found that businesses investing in reverse logistics saw up to a 50% reduction in overall logistics costs.

Make returns easy for customers

Your returns process should be as simple and intuitive as the purchase process. This includes providing clear return policies, prepaid return labels, and responsive customer service. A smooth experience encourages customers to shop with you again—even if the original purchase didn’t work out.

According to Accenture, 84% of consumers won’t make a repeat purchase if they have a poor returns experience.

Promote sustainability and reusability

Companies can reduce waste by focusing on refurbishing, reselling, or donating returned items. This not only saves money but also supports sustainability goals. Promoting your eco-friendly return practices can even boost your brand reputation and attract environmentally conscious consumers.

Reverse logistics as a competitive advantage

In today’s fast-paced, customer-centric retail environment, reverse logistics is more than just a backend process—it’s a strategic opportunity. Businesses that prioritize efficient and customer-friendly returns can reduce operational waste, save money, and boost customer loyalty.

By investing in the right systems, optimizing processes, and making the experience easy for customers, companies can transform reverse logistics from a cost center into a competitive advantage.

Make returns simple for your customers & smarter for you

nShift Returns delivers branded, self-service experiences while giving you the tools to prevent avoidable returns, automate refunds, and restock faster.

Discover moreFurther reading: Cost of poor reverse logistics FAQs

What are the hidden costs of poor reverse logistics?

Inefficient returns lead to increased transportation, storage, labor costs, lost revenue from unsellable items, environmental waste, and damage to brand reputation.

How much can retailers reduce logistics costs with effective reverse logistics?

Retailers optimizing returns can reduce overall logistics costs by up to 50%, recover around 12% of revenue, and minimize waste through resale and automation strategies.

What percentage of e-commerce purchases typically get returned?

Return rates in e-commerce range from approximately 15–30%, while brick‑and‑mortar stores see around 8–10% returns.

How much does it cost to process a return?

Processing a return can cost retailers anywhere from $3 to $6 per package, representing 20–65% of the product’s original value in handling expenses.

How much loss is tied to returns fraud and unsellable items?

Fraudulent returns make up approximately 14% of all retail returns, costing U.S. retailers around $100–110 billion annually. Many returned items lose value quickly or end up in landfill.

What role do data and automation play in reducing reverse logistics costs?

Analytics and automation allow retailers to forecast return volumes, detect fraud, optimize disposition, and recover up to 65% of value from returned goods. This reduces processing time and cost significantly.

How does poor reverse logistics affect customer loyalty?

A delayed or confusing return process increases customer dissatisfaction. In fact, 84% of consumers report not returning to a retailer after a bad returns experience.

Why is speed critical in returns processing?

Items sitting too long lose resale value. Quick grading and refurbishment help retailers recapture value before demand shifts or markdowns deepen.

About the author

Jyo Saikia

Product Specialist Director, nShift

With extensive experience in logistics, supply chain, and IT SaaS, Jyo specializes in helping businesses optimize operations and achieve sustained success. His deep industry knowledge enables him to craft innovative strategies that deliver tangible results, ensuring customers gain a competitive edge.